Portable magnetic flux leakage flaw detector MAGPORTABUR

MAGPORTABUR is the newest domestic high-performance portable non-destructive pipe control system with magnetic methods, designed for flaw detection of drill pipes (DP).

Magportabur is built on a modern element base, has a computerized control system, is mobile and differs from imported analogs with an acceptable price and the ability to work in low temperature conditions. Can be delivered according to the technical task of the Customer in the required configuration. MAGPORTABUR installation is designed for mobile control of the body of new and used DP (with landing, thread and / or clutch) with the parameters:

- diameter, mm from 60.3 to 168.3 (total 9 standard sizes of pipes),

- nominal wall thickness, mm from 7 to 13,

- length of pipe, m from 6 to 11.5.

Advantages of this equipment in comparison with competing imported products:

- low prices for spare parts,

- availability of detailed instructions for installation,

- The qualified support of the specialists of Group "Unitest" throughout the territory of Russia and abroad.

Nearest analogues: mobile installations of firms TUBOSCOPE and NEWTECH, having ultrasonic devices of immersion type in their structure for control of pipe ends.

Components of Magportabur:

- set of racks for placement of controlled pipes;

- coil magnetization / demagnetization of the body tube;

- mechanical trolley with electric drive to move the body of the coil tube

- magnetization with a basket of sensors and electronics for monitoring the pipe;

- cabinet power, control and data collection device (laptop);

- standard plant samples (SOP) for monitoring the operation of the plant and its calibration (by the number of standard sizes of controlled pipes);

- set of commutation cables;

- auxiliary device for installation installation.

Technical characteristics :

- The sensitivity of the control modules meets the requirements of GOST 631-75, ARISpec 5D, DS-1, GOST R 50278-92.

- The time of inspection of the body of the pipe is not more than 5 minutes

- Control capacity: up to 100 pipes per shift (determined by manual feed of pipes)

- Time of reorganization at change of diameter of a pipe no more than 30 minutes

- The error in monitoring the controlled length of the pipe is not more than 1%

- The coverage of the continuity of control along the perimeter of the pipe is 100%

- Operating temperature range:

- (+ 5- + 35) ° C for the power cabinet, and the device for collecting information,

- (-20- + 40) ° C for pipe elements moving through the pipe

- Continuous operation time per shift of not less than 10 hours

- Power consumption no more than 5kVA

- Unit weight not more than 500 kg

Installation options:

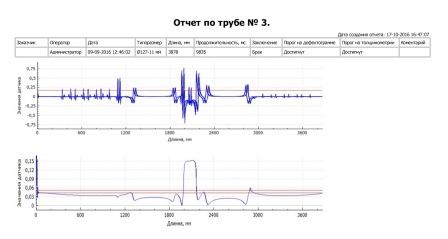

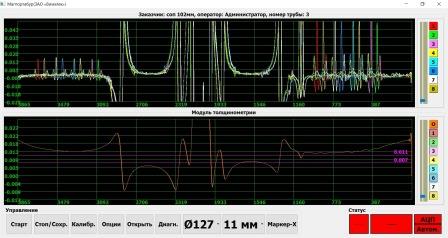

- the detection of internal and external transverse defects in the form of corrosion, as well as the risks and holes by the method of measuring the scattering of magnetic flux;

- monitoring of the state of the pipe wall thickness (assessment of wall thinning) by the method of measuring the magnetic flux density;

- Determining the length of the controlled part of the pipe body;

- automatic detection of detected signals and their excess over the exposed rejection levels;

- maintaining a database of control results and creating reports on the user's requests with the issuance of work statistics for any period;

- demagnetization of the pipe after inspection.

Brief description of the control process:

Before starting the inspection, the struts for the pipe are installed on a level platform. Equipment from the transport position is transferred to the working position, the installation is connected to the power supply source (220V 50 Hz). Monitoring of the functioning of the equipment and its calibration according to the reference pipe of the corresponding diameter are carried out. To do this, the reference pipe is installed on a pair of racks, a trolley with sensors and a magnetization coil are put on the pipe using an auxiliary device, the trolley drive, magnetization and measuring system power are turned on, sensor signals are recorded along the pipe body when the trolley moves between the racks, for example, from left to right. Based on the recorded signals from the reference pipe, the measuring system is calibrated.

Then the demagnetization mode of the pipe is turned on, in which the coil moves in the opposite direction and removes the residual magnetization of the pipe. The coil and the trolley are removed from the body of the pipe, and the reference pipe itself is transferred to the storage rack of the reference pipe. Installation is ready. When working with real DP, the pipe is loaded onto a pair of racks by the customer's lifting mechanisms, a portable installation for inspection of the pipe body is mounted on the pipe. Automatic control (defectoscopy) is carried out, the results of which are displayed on the laptop's display and entered into the database. At the end of the control and demagnetization, the DP is removed from the posts into a pack of fit or defective pipes. Simultaneously with the end of the control, the data collection and processing system issues a protocol for assessing the technical condition of the WT: the presence or absence of transverse defects and the condition of the walls of the pipe body, the location of the defects found and the data on the controlled length of the pipe.

Hits: 2132