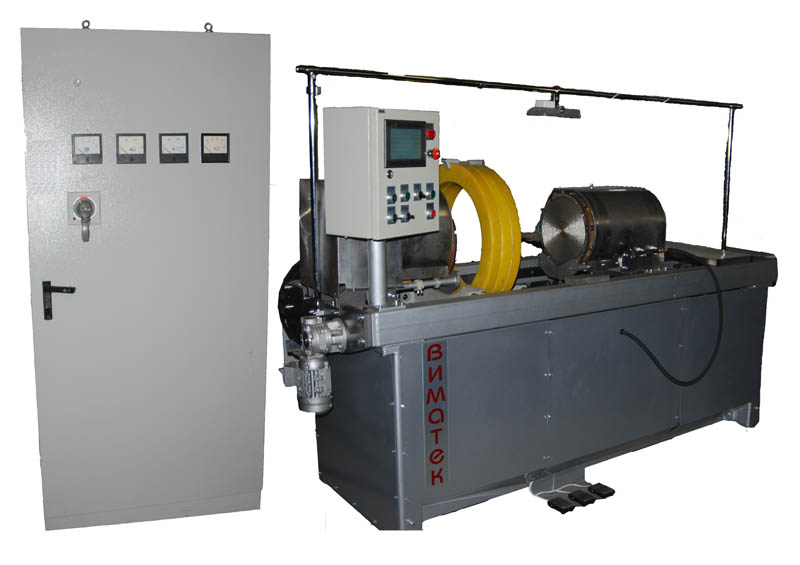

Magnetic Particle Flaw Detector Vimatec MDS-7

The magnetic particle flaw detector VIMATEC MDS-7 is the modern analogue of soviet flaw detector MDS-5. Now VIMATEC MDS-7 is the best universal MPI flaw detector in Russia.

Main features:

- The longitudinal magnetization can be realized, as pole from the electromagnets in the pasterns, and an annular electromagnet on the carriage with the actuator;

- The unique design of the contact plates, which allows to avoid "burn marks";

- The rotation of the contact plates not only for examination but also for magnetization by the operator;

- Current of the circular magnetisation up to 10000 A for 20 seconds long.

- MDS-7 may not contain pneumatic parts and does not require connection of the air;

- Not required cooling system;

- Easy configuration of inspection parameters, using the touchscreen.

- The storage controller controls used for the product range, it is possible to preserve the library's control regimes.

- Stepless adjustment of the magnetizing currents through solid state relays.

- Display the current settings of the control currents, etc.

- Highlighting both white and ultraviolet light.

Vimatec company can make the design changes, in agreement with the customer, to better meet customer needs.

The test object is clamped between attendants install. The inclusion of the buttons is actuated magnetizer.

In the process of magnetization or after the operator performs poured the controlled detail magnetic particle suspension using a hand shower with on / off button.

The object of control, sandwiched between attendants contact with the rotating plate can rotate by the operator. Visual survey details. After acceptance by the operator of the decision on the quality of components, it is demagnetized if necessary and removed from the installation.

| Circular current, А | 100-10000 |

| Magnetic Field between contact plates on 50 cm, up to, A/cm | 100 |

| Magnetic Field in the center of moveble annular electromagnet, А/cm | 250 |

| max weight of testing object, up to, kg | 50 |

| max lenght of testing object, up to, cm | 2500 |

| Power, kW | 110 |

Magnetic Particle Flaw Detector Vimatec MINIMAG-1000

Magnetic particle flaw detector MINIMAG-1000 open low-cost line of flaw detectors and differs by the following features:

- Modern, comfortable flaw detector for a reasonable price;

- Implemented the sealing parts manual by lever, to control the small items;

- Longitudinal magnetization is implemented, as pole from the electromagnets in the pasterns;

- The unique design of the contact plates, which allows to avoid "burn marks";

- The rotation of the contact plates not only for examination but also for magnetization;

- Software managing controller allows flexible and easy to modify the control regimes for various items of control objects.

Among the main advantages of magnetic particle flaw detector MINIMAG 1000 note:

- Easy configuration of inspection parameters, using the touchscreen.

- The storage controller controls used for the product range, it is possible to preserve the library's control regimes.

- Stepless adjustment of the magnetizing currents through solid state relays.

- Display the current settings of the control currents, etc.

- Highlighting both white and ultraviolet light.

"Vimatec" can make the design changes, in agreement with the customer, to better meet customer needs.

The flaw detector MINIMAG-1000 is a standalone unit with manual loading of parts, manual discharging and visual inspection.

The object of control, sandwiched between attendants contact with the rotating plate can be rotating by the operator.

| Current of the circular magnetization, А | 100-5000 |

| Magnetic field between contact plates with 500 mm, up to, А/m | 10000 |

| Max weight of test object, kg | 10 |

| Max lenght of test object, mm | 1000 |

| Power, kW | 50 |

| Вес, кг | Не более 500 |

| Занимаемая площадь цеха, м2 | 4.5 |